In our mission to give a platform for those at the top of their game, Armand from Praxis Glass was one of the people that we knew we had to reach out to. Aside from the array of Praxis pieces in my personal collection, seated just to the side of me, we have also been stocking Praxis Glass on our LOUDcpt store for quite a while now.

The glass industry can be a challenging one, especially with the white-label nature that engulfs the market. This is most true for artisinal glass makers who see glass as an art medium and, unlike mass-produced glass, attempts to create something with individualistic flare and allure. The biggest challenge in the current times, and especially in South Africa, is the financial side.

Mass produced glass is typically created from cheaper materials and with far less time or creative attention paid to the product being made. In many cases, the individuals creating the designs and pieces have no history of smoking cannabis or even interest in the plant. These are the types of bongs you find in shops on the outskirts of shopping malls, with a generic Rick & Morty sticker on them. And while one’s preferences are entirely subjective, there is more to bongs, rigs and pipes than just mass produced glass.

There lies, instead, behind the scalding heat and discomfort – a passionate artist that, in most cases, has a deep appreciation for cannabis culture. So while we understand that mass produced glass may be convenient, just know that there are ways to support those within the industry while at the same time elevating your smoking experience with craft glass. Works of art that offer far more than just a way of getting high.

Buckle in as we discuss Praxis’s work, his thoughts on the glass industry and also some of the challenges local glass makers face.

Firstly, for those who may not know of Praxis – briefly introduce yourself and tell us what it is you do.

My name is Armand; I work under the name Praxis Glass. I create functional and non-functional glass art through the process of flameworking.

How long have you been working with glass, and did your interest in glass start as a desire to create smoking accessories?

I started out shadowing a scientific glassblower in JHB back in 2012, right out of high school. My interest in glass was certainly fueled by my interest in pipes. I wanted to create pipes and bongs, but had never seen the process. I took my chances making pipes right under my mentor’s watchful eye. After months of experimentation, he finally caught me, and I was asked to leave.

You’ve created a number of custom pieces for the cannabis community in recent years. What was your favourite piece so far, and could you tell us a bit about what makes it special to you?

I have at least three or four pieces that come to mind. Usually, the more colour prep-heavy designs and usually recyclers. The pieces with larger budgets allow me to invest more time into a piece and hence be more creative with the colour palette and design.

The term “heady glass” is a somewhat subjective one. How would you define the term personally?

To me, any piece that evokes deep thought and appreciation can be considered “heady.” I tend to think of “heady” as referring to the cerebral effect and input that goes into a high-end glass piece. The amount of attention to detail, thought, and ingenuity that can go into a piece determines its “headiness.” A heady piece feels like an important artifact.

The function of a piece is something that is often overlooked when you’re learning to create a new function for the first time – is this something you tend to nail on the first few tries, or is there a time-consuming learning process to ensure that the function works as it should?

I think it’s one of those things you get the hang of the more you play around with function and how the water acts within a given shape. Without straying too far into new territory, you can usually nail the function every time. Only the first few instances should have noticeable flaws.

Without giving too much away, are you busy learning any new techniques at the moment, whether it be colour techniques or functions?

No particular colour prep techniques that I am currently working on besides perhaps sleeving most of my prep. Which just means coating coloured/patterned glass in clear glass without trapping any air. Further I am currently working on some bloopers and incorporating a swirl into the blooping function too.

What is something that you see a lot of people get wrong about glass blowing that you’d like to correct the narrative on?

That it’s a cash grab. So much time, effort and cost goes into making higher-end glass that there really are easier and better ways of making profits than sweating hours over a piece of glass to reap a narrow margin. There are exceptions, but most flameworkers are working for a pittance. Also that all glass is made equally. It’s a whole industry unto itself, and there is a wide spectrum of craftmanship levels.

When a glass artist goes about learning new styles and ways to work with colour, what does that process typically look like? And how long does it typically take to learn and then master that style?

A lot of swearing, crying, and rageful fits, hahaha no, but mostly a lot of loss. In terms of time and expensive resources used. The time and amount of tries can vary a lot and will depend on both the abilities of the flameworker, the range of tools to your disposal and the difficulty of the technique involved. But it can take months to get comfortable with certain techniques.

Every artist is inspired by the works of others; who are some international glass artists that have inspired you?

Honestly, too many to mention. I draw inspiration from hundreds of artists. Mike Shelbo, Swan Glass, Contrabasso, Salt, Eusheen, SDRyno, Hefe Glass, Jenkins Glass, and so many more. I could just sit all day and list cats I look up to.

Do you find that customers who provide a digital rendering or sketch of the glass piece make the process of creating it easier than those who offer verbal/written instructions on what they’re looking for?

Frankly, I don’t really like executing designs that way for the particular reason that the client doesn’t know the medium and what is practical or within my range of capabilities. So custom work is a trusting process, we usually discuss some examples of my previous work to establish an idea, and from there, I prefer having creative control over the project. I only have access to a slither of colour at a time. Some colour is trickier to work than others or are preferred for certain applications. It can get tricky and murky for a client really quickly. So as long as they can trust me, it works best that way.

Some people think that blowing glass is as simple as a one-sitting session. Provide some insight into what the typical process is for an average-sized rig and how long that work typically takes?

Depending on the level of complexity, I typically take 2-3 working days to finish off my more complex recyclers. Every piece goes through stages, the first being prep. If colour is used, the prep needs to be made or gotten ready for the application. Sections are then preshaped into a variety of components, downstems, uptakes, percs, can and top chamber, etc. The last stage is assembly and usually the more stressful part, where all the work comes together or fails spectacularly. Smaller, less intense rigs typically take me a day to complete, given that it’s not colour prep heavy design.

By now, most people have seen the term “borosilicate glass,” and many assume all borosilicate glass is the same. What’s the real story there?

There are a few different companies that manufacture borosilicate tubing and rod. These include Schott Duran (the OG Germans), Pyrex (Formerly American- now Czech-made), Simax (hailed for its clarity and quality), and Chinese/Indian borosilicate. European and American glass, being held to a much higher manufacturing standard and environmental laws, costs much more than Asian-made glass. Chinese glass is often found with stones and contaminants in the glass.

Could you explain what fuming is and how resin can impact the appearance of a fumed piece?

Fuming is the process of depositing gaseous pure silver and gold on to the surface of the glass and then trapping it in place with more glass or “baking” it on to the glass.

So as a piece is used and the resin builds up against the inner surface of the glass, it provides a “backdrop” for the infused silver and gold, allowing it to show off its brilliance truly. Once the piece is cleaned, it returns to its original state.

What are some of the biggest challenges of being a local glass maker, both in terms of your craft and the market?

Well, locals are still very skeptical about artisanal glass. I get the feeling many folk think I am out to hoodwink them or get them to buy into a fad. Most locals only have experience using Asian production glass made on an assembly line. I like to call it “imitation glass.” So most people that like glass think this imitation glass is what all glass functions like or that all glass has the same level of durability, which obviously couldn’t be further from the truth. So it’s certainly an uphill battle in terms of convincing people what I do is worlds apart from soulless assembly work. Besides that, the importation of glass and tools ranks just about as high. Everything I use needs to be imported, which means I end up paying between 2-4 times what Americans pay for tools and materials. That, combined with a local market that undervalues my craft, has certainly made it very difficult to create.

Everyone has their own ways of cleaning glass, but as someone who creates the pieces. What methodology do you recommend for cleaning pieces?

Regular maintenance is key. I can’t stress that enough. Clean your piece weekly, and you will never run into issues and have cleaner, tastier rips every time.

I use a combination of Ethanol 96% and soapy water. I first empty my piece of water. Throw some ethanol in her, then for a quick microwave of about 20 seconds, plug the holes with toilet paper, but add salt if needed. Then shake vigorously and empty, rinse with dishwashing soap and water till she gleams. Hot water, and warm ethanol are game changers; warmer solvents work better at getting that stubborn resin off. Never shock your piece, though. Always heat it gently and with care. Same goes for cooling.

America has its own glass-blowing culture, where communities of glass-blowers will set up entire art exhibitions with dozens of artists. This also leads to tightknit glass-blowing communities. What do you think both South African glassblowers and heady consumers could do to encourage this type of growth locally?

We need to include local glass in social events around the plant and hash. Get flameworkers to do demos and get people engaged. My theory and mission are to inspire as many as possible to take up to the torch locally. The way I see it, more flameworkers, means more collectors, which leads to these sorts of events becoming more viable and closer to reality. That being said, we are potentially decades away from reaching that sort of level of interest locally. I’d love to be part of that change, though. If I could reach a point in my career where I can afford it, I would love to offer courses and shop space for people to have direct exposure to molten glass.

Many find it challenging to understand why heady glass costs more than their corner-store counterparts. Could you help give some insight into what creates the higher costs and why they’re, in many cases, unavoidable?

Well Asia is really good at breaking a product down into its base components and then assembling it into something that resembles the real deal. So China and India solved the issue of expensive glass tubing and rod by making their own, bypassing stringent quality control present in Western manufacturers. They solved the issue of labour by breaking a piece down into x-amount of steps and dividing those steps between a dozen or whatever assembly workers. So a person will sit there all day and only complete one step in the process before passing it on to the next guy, and so it goes. No pride or dignity is taken in the object being created. In more advanced systems, whole parts of manufacturing are automated even.

So on the flip side, I work with Western-made materials mostly, which cost a lot more than Asian made glass. I complete all the steps in a meticulous fashion. Every component is shaped and reshaped until I am satisfied with it. Every seal is obsessed over until the glass flows to my satisfaction. Expensive glass is thrown away and wasted in the process many times. My gasses (oxygen and LPG) along with the electricity I use are also big continual expenses in making glass. Kilns need maintenance, and tools perish. All these are big expenses in the pursuit of making worthwhile glass. So essentially, you are paying for my time, the glass, gas, electricity, and tools that go into making said glass piece. Some of the most well-known and respected glassblowers have been heard claiming to earn as much as a waiter. Well, my sister is a waiter, and she certainly makes more money than I do. You don’t stay in this for the money.

If social media is good for one thing, it’s got to be the ability to connect with knowledgeable individuals around the world. Do you have other glassmakers in other countries who have helped you in refining your skills or assisting with any technical nuances?

Yes, most certainly. I have reached out to many and have been surprised at the level of assistance many are willing to give me. At the end of the day, most glass makers are very passionate about the medium, and they want to spread that appreciation as far and wide as they can.

Heady glass and extracts tend to go hand-in-hand. What’s your favourite type of extract to smoke on (hash, hash rosin, flower rosin, BHO, crystals, etc.)

Hash Rosin, without a doubt

You’ve no doubt created a number of pieces that never hit the market. What does your personal glass stash look like?

You’d be surprised; I usually get left with the prototypes and imperfect pieces. I am seldomly in a position to be able to keep the pieces that I really like, and setting aside the resources to make myself something isn’t really ever on the table either.

Learning new techniques is often achieved in a similar manner as the tattoo industry by shadowing an experienced artist with more experience, who can guide one through what becomes a complex art form. Do you find that the limited number of glassblowers makes the process of being a skilled glassblower a lot more difficult than in countries like America?

Yeah, it’s a factor. Over there, there are many classes, schools, and social events centered around borosilicate and, in some cases, even focused on pipes. So naturally, that has an inertia of sorts. So many brilliant minds bouncing off each other and propelling things forwards. Just taking a class with some of these heavyweights ought to be life-changing if applied.

Although there is so much information at your fingertips these days, two three-hour-long instructional videos that go into detail about the process and break it down, Torchtalk and Revere glass on Youtube, come to mind. So with enough willpower it is very much possible to become a proficient flameworker locally.

But having more torches in more garages in your city or state, probably increases your chances of being able to try it out for yourself.

For those who find the art of glass alluring to them, how do you recommend one begin working with glass?

I would reach out to as many glass-related businesses as I could locally and try to get my foot in that way. If your wish is to learn about scientific glassblowing, reach out to glassblowing companies regarding apprenticeships. Watch as much footage on the particular branch of glass you are interested in. It might be that the only way in is to take the plunge and buy the equipment even. After my short apprenticeship, I applied for personal loans to acquire my own setup. I worked retail sales and merchandising for five years in order to pay off the loans. Point is, it might not be easy or quick, but if you really put your mind to it, it’s possible. Feel free to reach out to me for any guidance too.

You take commissions as well as supply a few headshops (including our own). For those interested in getting a custom piece, where can they contact you?

+27 81 799 8224

Or Instagram

Our Praxis Glass Stock (Shipped Across South Africa)

-

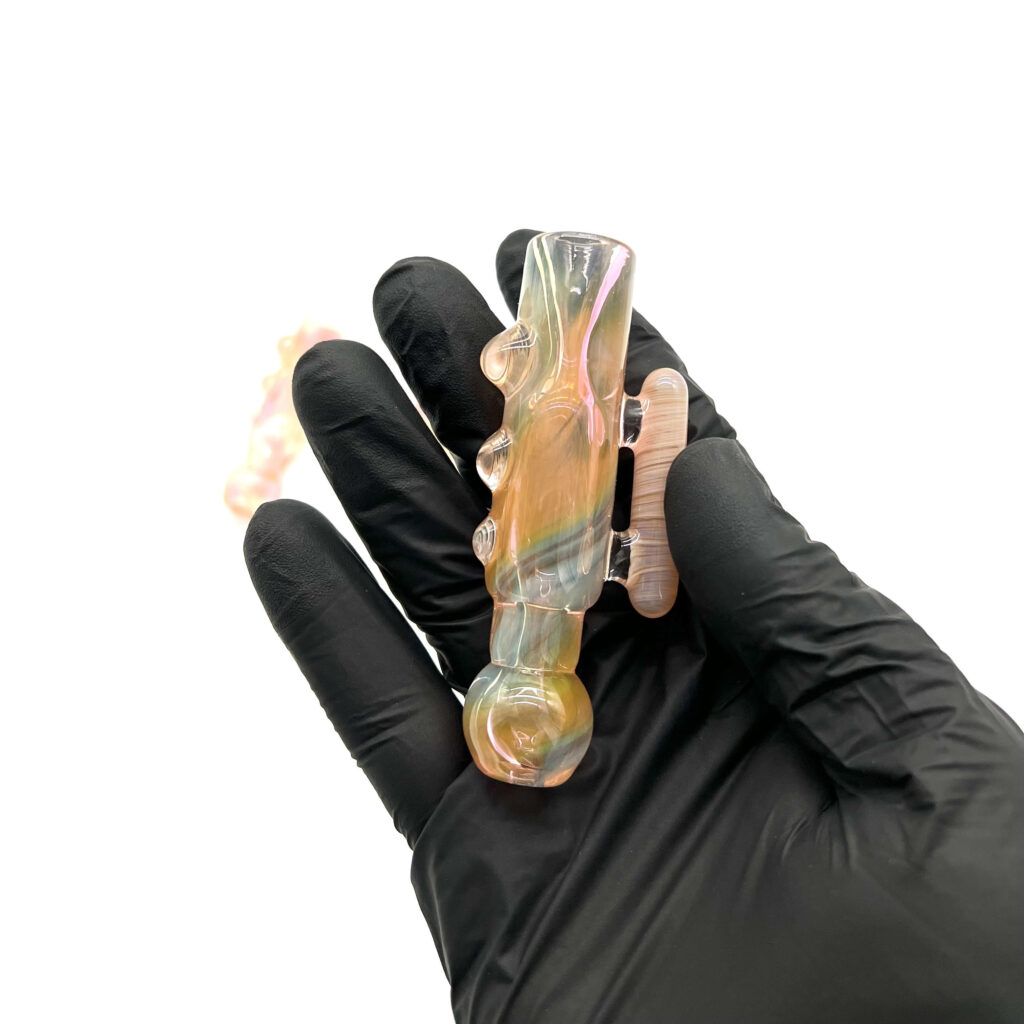

Praxis Glass – One Piece Sherlock

Praxis Glass – One Piece SherlockR1,000.00

R600.00 -

Praxis Glass – Voyager 2.0 [No Handle]

Praxis Glass – Voyager 2.0 [No Handle]R600.00R360.00 -

Praxis Glass – Voyager 2.0 [With Handle]

Praxis Glass – Voyager 2.0 [With Handle]R700.00R420.00 -

Praxis Glass – Pink Gill Sealed Rig

Praxis Glass – Pink Gill Sealed RigR2,990.00R1,794.00 -

Praxis Glass – 4-Hole Bowl and Poke Yellow WoodgrainR1,000.00

Praxis Glass – 4-Hole Bowl and Poke Yellow WoodgrainR1,000.00

Leave a Reply